| ||||||

Custom Fine Furniture by Alan Young

Making the Legs

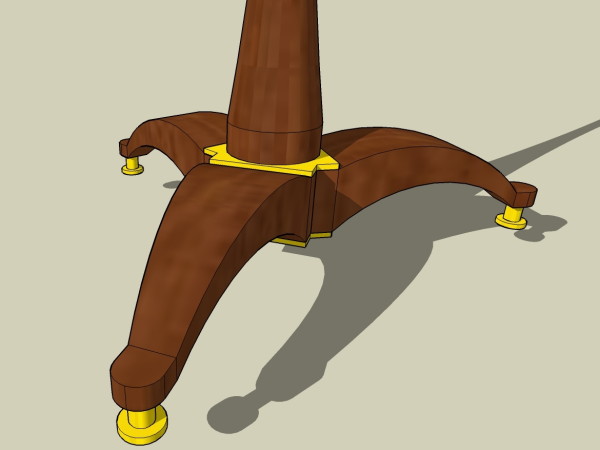

The feet are ready to be glued.

The trip pod leg design calls for double loose tenon joinery to a triangular center block seen in the previous page.

I could print out a scaled drawing of the profile, trace it to the stock and then cut it out but I in this case I'm going sort of "free-hand" the profile.

My drawing shows the general shape I want for the legs.

I like to save odd shaped pieces from other projects-these can yield interesting curves that can be used for drawing lines. In this case I'll use several cutoff pieces and miscellaneous parts to draw my profile

I know the general shape I want- First I'll mark the line where the curves end near the joint.

Next I use this strip of plywood to mark the "height" of the foot's pad.

Now I use the cutoff sections to mark the shape of the top curve

Then a line to mark the "length" of the pad.

This walnut cutoff is used to mark the curve for the underside.

That radius was too tight- so I drew in a larger radius curve below the line.

The side profile is now ready to cut on the bandsaw.

Now to draw the profile for the top. I will make the footpad round using this brass pully.

The width of my square is pleasing enough for the lines from the round pad to the end of the curve.

Using a thin strip ripped from some previous stock, I connect the round pad to the lines where the curves start.

Now it's back to bandsaw to cut the top profile.

I'll save these pieces for my curved cutoff bin. Looks like I might have a foot for another project down the road.

A bit of shaping and sanding then....

Back to:

On to: